High pressure dosing units

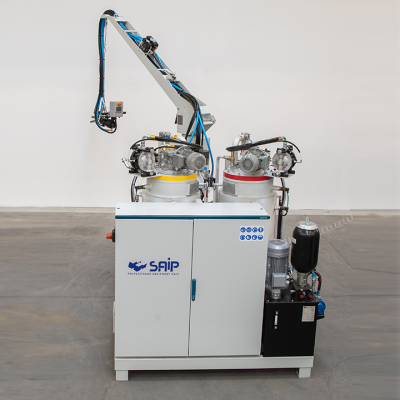

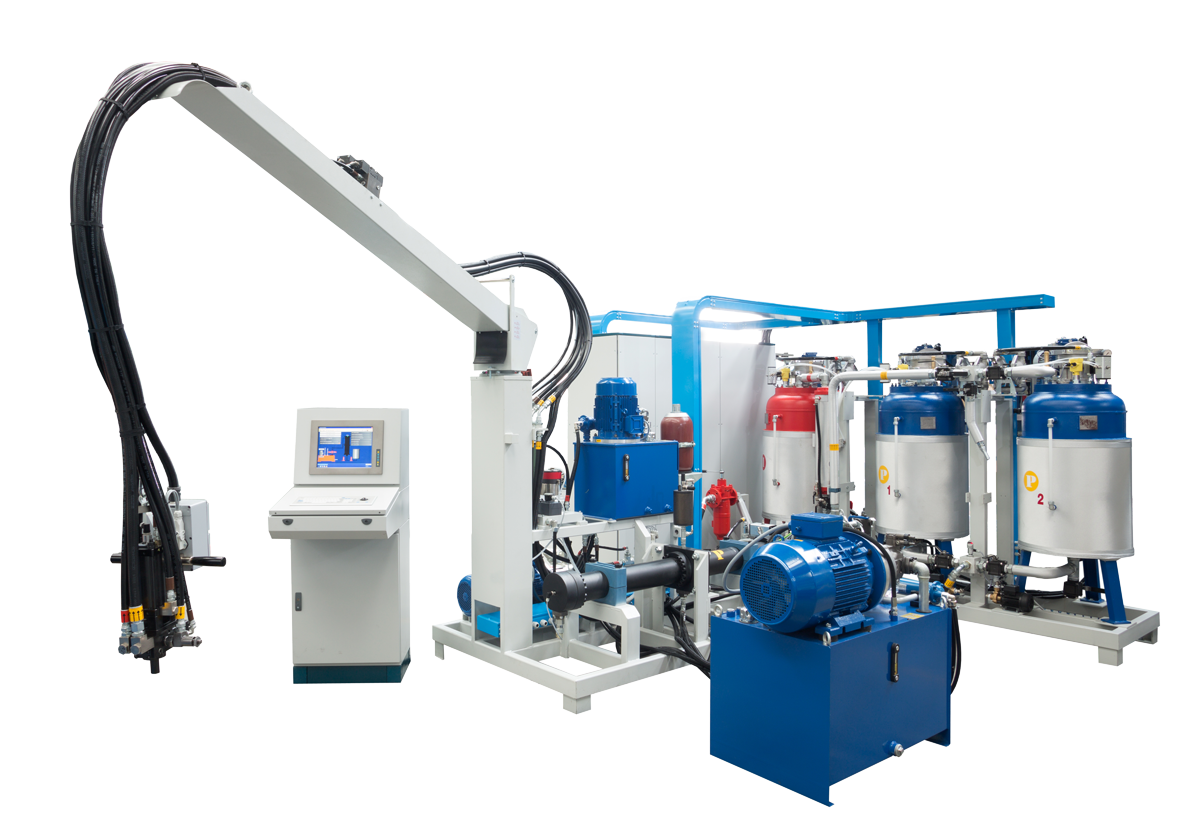

SPB dosing unit

SPB dosing units, designed for industrial use, are equipped with various accessories to maximise control and ensure optimal operation.

SPB machines are ideal for fulfilling any production requirement and are available with a variable output from 10 to 300 kg/min. and component ratios ranging from 1: 5 and 5: 1. SPB units have manual flow rate and component ratio control; they can be operated by a PLC and control panel with touch-screen or by an industrial PC, which allow the work parameters to be set and displayed.

The inverter for infinite flow and component ratio variation is available as an optional component. SPB machines are suitable for polyurethane foams made with HCFC’s, HFC’s, HFO’s, methyl formate and water with or without blowing co-agent.

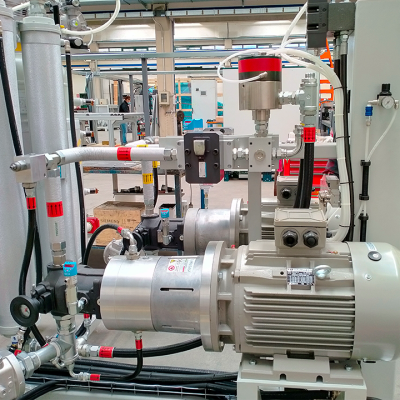

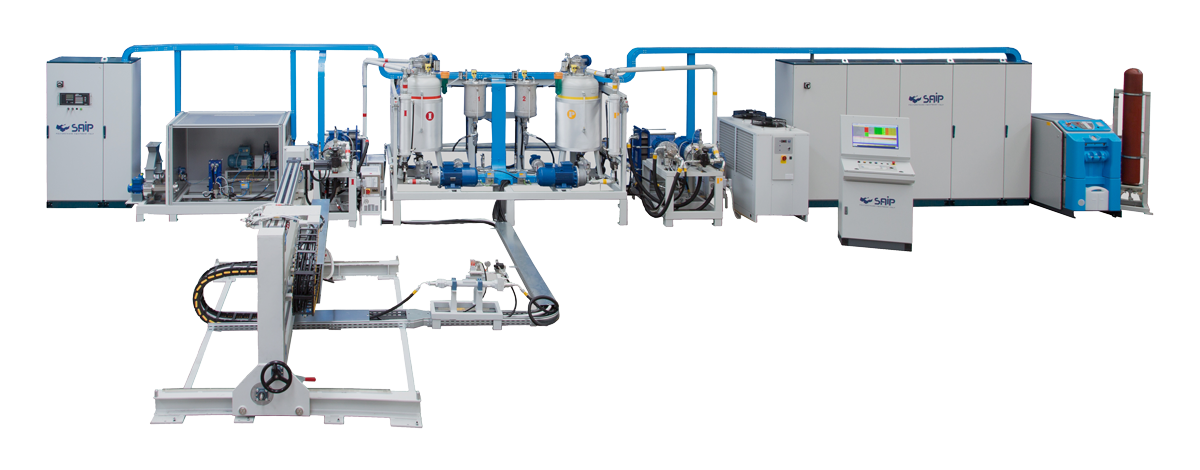

SPBS dosing unit

SPB dosing units are specially designed for specific applications requiring technologies such as RIM, RRIM, infusion, etc.

Thanks to a special dosing cylinder, the polyol can be mixed with additives and special fillers without any problems for the machine, resulting in a product with excellent physical and mechanical properties.

Closed-loop variation of the flow rate and component ratio allows infinite adjustment of the work parameters to achieve the desired hardness and density.

The multi-component dosing tanks with their valves allow for precise dosing and mixing of different materials and colours, without the need to clean the entire line.

Special software ensures recycling mode during non-working periods and weekends.

SPB machines can be easily coupled to anthropomorphic robots or multi-axis manipulators and work fully automatically with rotary tables, carousels and any system where a high degree of automation is required.

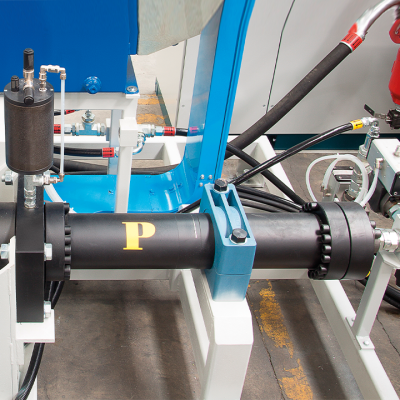

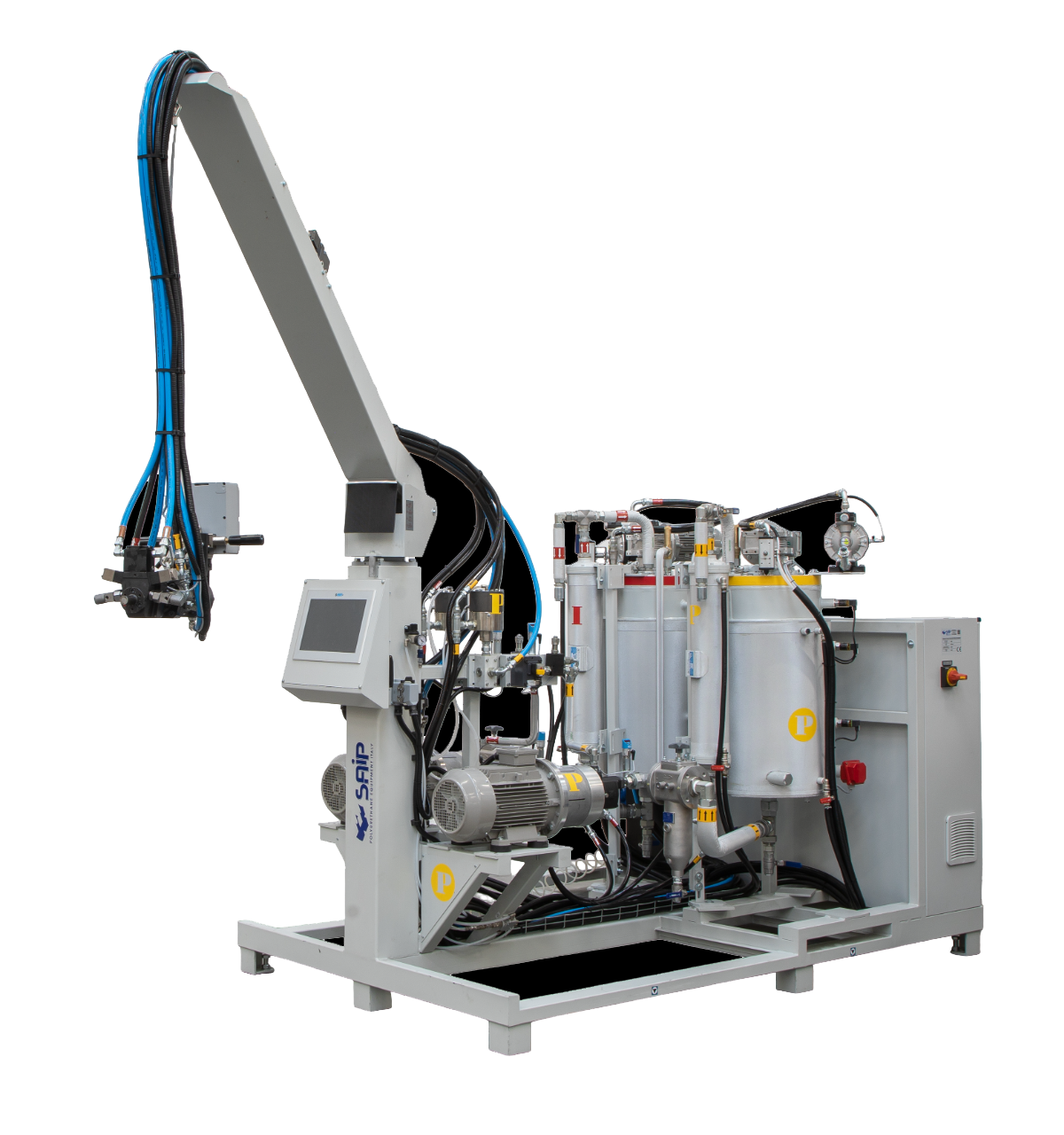

SP PENTA dosing unit

SAIP SP PENTA is a high-pressure dosing machine designed for the use of pentane and other blowing agents.

SAIP designs and manufactures customised solutions with a focus on configuration and safety features, considering the use of flammable blowing agents.

La fornitura comprende:

Supply includes:

– In the continuous process:

- LPS technology: pentane (or other hydrocarbon) is added to the polyol and mixed through a dynamic mixer in the low-pressure stream of the polyol and then sent to the high-pressure stream of the polyol before reaching the mixing and dosing head of the foaming machine;

- HPS technology: pentane (or other hydrocarbon) is added to the polyol and mixed through a static mixer into the high-pressure flow of the polyol just before reaching the mixing and dosing head of the foaming machine.

– In the batch process:

- PBS system: the pre-mixing of polyol and hydrocarbons;

- RTU system: ready-to-use pentane/polyol mixture;

- PTS system: injection of the third component.